Wood finger-jointing is a vital process in the woodworking and furniture industries, allowing manufacturers to create longer, stronger, and more dimensionally stable wood products by joining shorter pieces together. At the heart of this technique lies a crucial component: wood finger-joint adhesives.

Choosing the right adhesive for finger-joint applications is critical to ensure strong bonds, smooth processing, and durability in finished products. TECHBOND proudly offers high-quality water-based PVAC (polyvinyl acetate copolymer) adhesives specifically formulated for wood finger-jointing. In this post, we will explore the importance of selecting the right adhesive, the advantages of water-based PVAC adhesives, and why TECHBOND is your trusted partner in adhesive solutions.

Understanding Wood Finger-Jointing

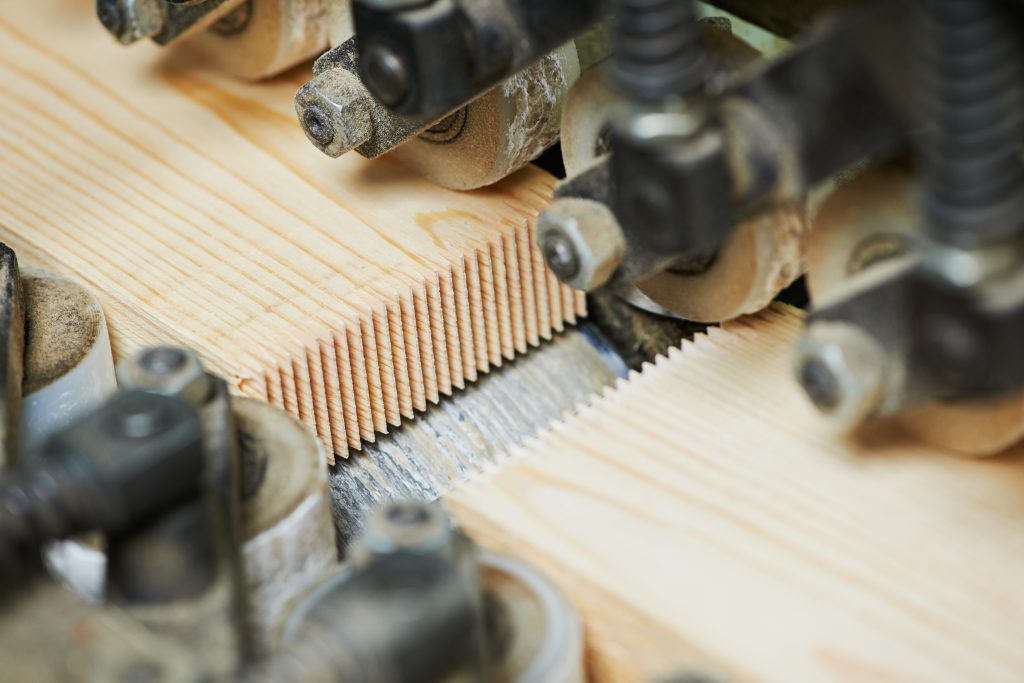

Before diving into adhesives, let’s briefly look at what finger-jointing is. Finger-jointing involves cutting matching rectangular “fingers” into the ends of two wood pieces and gluing them together to form a strong, extended board. This technique is widely used in furniture making, flooring, door frames, and panel manufacturing.

Wood Finger-Jointing

Finger-jointed wood offers several benefits:

-

Efficient use of resources: Smaller, less expensive wood pieces can be turned into premium products.

-

Strength and stability: Well-bonded finger joints can be as strong or even stronger than solid wood.

-

Sustainability: It minimizes waste, making wood use more eco-friendly.

However, all these benefits depend heavily on the quality of the adhesive used.

What Makes a Good Wood Finger-Joint Adhesive?

The adhesive must be carefully chosen based on the specific needs of the finger-jointing process. The key requirements include:

-

High bond strength: To ensure the joints can withstand mechanical stress and environmental changes.

-

Fast setting time: To maintain high production speeds without compromising quality.

-

Heat and moisture resistance: Essential for wood products used in diverse climates or exposed to varying humidity.

-

Easy application: Consistent viscosity for easy spreading and efficient machine application.

-

Eco-friendliness: Low VOC emissions to meet modern environmental and worker safety standards.

TECHBOND’s water-based PVAC adhesives are engineered to meet and exceed these demands.

Why Choose Water-Based PVAC for Wood Finger-Joint Adhesives?

At TECHBOND Vietnam, we specialize in developing water-based PVAC adhesives designed specifically for woodworking applications like finger-jointing. Here’s why PVAC is the ideal choice:

1. Strong and Durable Bond

PVAC adhesives provide excellent adhesion to wood surfaces, penetrating the wood fibers deeply to create strong, reliable bonds. In finger-joint applications, this ensures that the joined pieces perform just like or better than solid wood.

TECHBOND specializes in developing water-based PVAC adhesives designed specifically for wood finger jointing

2. Fast Setting Time

Efficiency is key in modern manufacturing. TECHBOND’s PVAC adhesives offer fast setting times, allowing for higher production speeds without sacrificing bond quality. This results in better productivity and lower production costs.

3. Good Heat and Moisture Resistance

Wood products often face fluctuating temperatures and humidity levels. TECHBOND’s specialized formulations provide enhanced heat and moisture resistance, helping the finger joints maintain their integrity and appearance over time.

4. Easy to Apply

Our PVAC adhesives have an optimized viscosity that makes them easy to apply either manually or through automated finger-jointing machinery. This ensures uniform adhesive coverage, which is critical for consistent bonding strength across joints.

5. Eco-Friendly and Safe

Being water-based, TECHBOND’s PVAC adhesives are low to free VOCs, making them safer for workers and more environmentally friendly. We are committed to supporting sustainable manufacturing practices through our adhesive technologies.

Water-Based PVAC for Wood Finger-Joint Adhesives

Applications of TECHBOND’s Wood Finger-Joint Adhesives

Our wood finger-joint adhesives are widely used in:

-

Furniture manufacturing

-

Flooring production

-

Door and window frame assembly

No matter your specific application, TECHBOND offers tailor-made adhesive solutions to match your production requirements.

Why Partner with TECHBOND Vietnam?

With years of experience in adhesive manufacturing, TECHBOND Vietnam is a trusted name in the woodworking and packaging industries. Here’s what sets us apart:

-

Customization: We work closely with clients to provide adhesives tailored to their specific production needs.

-

Consistent Quality: Our advanced production processes and strict quality control ensure product consistency and reliability.

-

Technical Support: Our technical team provides on-site support, from adhesive selection to production optimization.

-

Innovation: We continuously research and develop new adhesive technologies to meet the evolving needs of the market.

When you choose TECHBOND, you are not just buying an adhesive—you are gaining a partner dedicated to your success.

TECHBOND Vietnam is a trusted name in the woodworking and packaging industries

Conclusion

Selecting the right wood finger-joint adhesive is crucial for the strength, durability, and efficiency of your products. TECHBOND’s water-based PVAC adhesives offer the perfect combination of strong bonding performance, fast setting, environmental safety, and ease of use.

If you are looking for a reliable adhesive solution for your finger-jointing processes, look no further than TECHBOND Vietnam. Our high-quality PVAC adhesives are designed to enhance your production and ensure outstanding results.

Contact us today to learn more about our adhesive solutions and how we can support your manufacturing needs!

Not sure which adhesive is right for your application?

Get in touch with us today for expert advice