When it comes to woodworking, furniture manufacturing or general wood-based production, the right adhesive makes all the difference. In this article, we focus on the keyword “wood glue”, exploring what it means, how it works, and why selecting a trusted supplier like TECHBOND can elevate your bonding performance — including their key technologies in water-based and hot melt adhesives.

What is Wood Glue?

“Wood glue” is a general term for adhesives formulated specifically to bond wood to wood, and often wood to other materials. The function is to create a durable, strong joint that resists stress, moisture, and separation over time.

“Wood glue” is a general term for adhesives formulated specifically to bond wood to wood, and often wood to other materials.

For manufacturers, this means choosing an adhesive with the right set of performance properties (strength, open time, cure time, resistance, etc.).

TECHBOND is a manufacturer that explicitly serves the wood-based industry with adhesives designed for woodworking and related production.

Why the Right Wood Glue Matters

Bond Strength & Durability

Quality wood adhesives enable high bond strength. They help ensure the joined wood doesn’t separate under load, expansion, or contraction. According to industry insight, wood glue offers “high adhesion … and good strength … water and chemical resistance.”

Compatibility with Wood Substrates

From softwoods to hardwoods, from veneers to engineered panels, each substrate has different challenges such as density, moisture content, surface condition, oily or resin‐rich species. A manufacturer like TECHBOND designs water-based adhesives that are compatible with “various wood types including softwood, hardwood, oily woods, and even difficult‐to‐bond surfaces”.

Processing Efficiency & Productivity

In modern production lines, speed and consistency are crucial. Hot melt adhesives, for example, offer rapid set times and minimal drying time, reducing cycle time and enabling high throughput.

Environmental, Health & Safety Considerations

Adhesives that minimise solvent or VOC emissions, or that work in lower energy processes, provide benefits from regulatory, worker-safety and sustainability perspectives. TECHBOND emphasises water-based adhesives with no solvent and low VOC.

TECHNOLOGY SPOTLIGHT: Water-Based Adhesives from TECHBOND

One of the key adhesive types for woodworking is the water-based adhesive (often PVA, VAE or other polymer emulsions).

What They Are

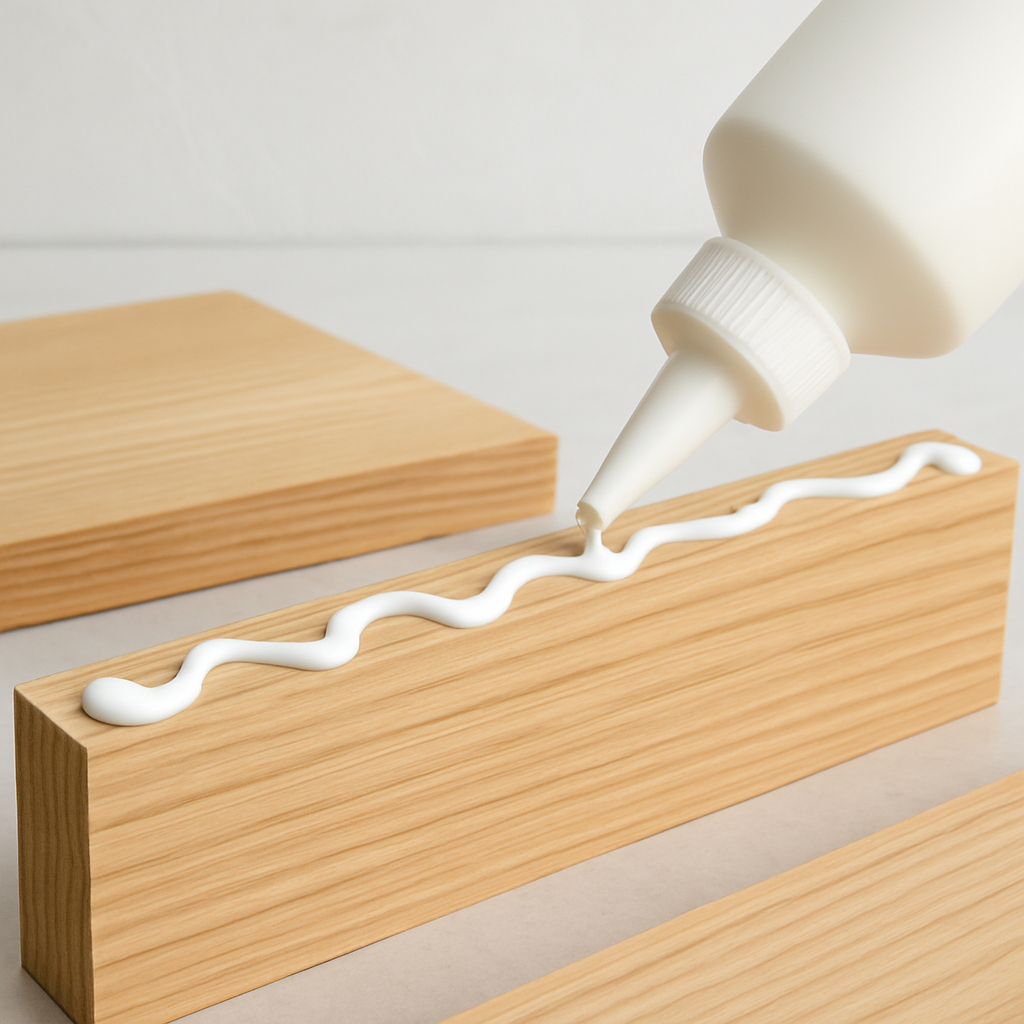

Water-based adhesives are typically milky-white liquid polymers. They rely on water evaporation and polymer film formation to create the bond. They are well suited for porous substrates like wood. According to TECHBOND: “Water-based adhesives … are widely used in the production of indoor and outdoor wooden furniture.”

TECHBOND D4 water-based adhesive for wood lamination

Key Features from TECHBOND

-

Certified to DIN EN D2, D3, and D4 standards (important for moisture / structural performance).

-

Compatible with a wide range of wood types (softwood, hardwood, oily woods) and with processes like cold press, hot press, high-frequency press.

-

Because they are water‐based, they avoid many of the solvent hazards and often align with sustainable manufacturing practices.

When to Use Water-Based Wood Glue

-

When working with porous wood surfaces and standard pressing conditions.

-

When you require structural strength but you have time for the adhesive to cure via evaporation or pressure.

-

When you want a cost-effective solution for many wood‐to‐wood assembly tasks (lamination, finger jointing, veneering).

Benefits & Considerations

Benefits: Good adhesion, compatibility with wood, recognised standards compliance.

Considerations: Drying/curing time may be longer than instant adhesives; less suitable for non-porous or difficult substrates unless specially formulated.

TECHNOLOGY SPOTLIGHT: Hot Melt Adhesives from TECHBOND

Another major adhesive category relevant to wood manufacturing is hot melt adhesives. TECHBOND’s offerings include EVA, PO (polyolefin) and PUR hot melts.

What Are Hot Melt Adhesives?

Hot melts are solid at room temperature (sticks, pellets, blocks) and are applied molten via heated applicators. Upon cooling, they form a bond. They do not rely on evaporation or chemical curing like solvent or water-based adhesives.

Edge banding with hot melt adhesive solutions from TECHBOND

Key Features from TECHBOND

-

Fast setting time: ideal for high speed production.

-

No drying or curing required: cuts down on cycle time, energy consumption.

-

Good adhesion to a broad variety of substrates including challenging ones (coated boards, plastics, metals) via PO adhesives.

-

TECHBOND offers tailored formulations and technical support.

When to Use Hot Melt for Wood Applications

-

Edge-banding, profile wrapping, lamination of boards where speed is critical.

-

Bonding engineered panels where there may be less porosity or surfaces are pre‐finished/coated.

-

Production lines where downtime has to be minimal and high output is required.

Benefits & Considerations

Benefits: Instant set, clean application, minimal waste, high efficiency in production.

Considerations: Requires equipment for melting/application, less forgiving in open time (you have to work fast once applied), substrate preparation still important. Also often higher upfront equipment cost.

Choosing Between Water-Based and Hot Melt for Wood Glue Applications

To decide between water-based vs hot melt adhesive solutions for wood bonding, you should evaluate several factors:

1. Substrate & Surface Condition

-

Porous, untreated wood surfaces → water-based adhesives work very well.

-

Engineered wood, coated boards, laminated surfaces, mixed materials → hot melt (especially PO or EVA type) might be more suitable.

2. Production Workflow & Speed

-

If your process involves pressing and awaiting drying/curing over some time, water-based is an excellent fit.

-

If you are in a continuous, high-speed line (edge banding, lamination, profile wrapping) where speed is crucial, hot melt is advantageous.

3. Environmental/Regulatory Considerations

-

If solvent exposure or VOC emissions are a constraint, water-based adhesives from TECHBOND (with no solvent, low VOC) are a strong choice.

-

Hot melt adhesives also typically avoid solvents and can deliver clean bonding; but you must ensure the formulation meets your needs.

4. Bond Requirements (Strength, Moisture, Use Case)

-

If the joint must meet higher moisture resistance (DIN EN D3/D4) or be used outdoors, ensure the epoxy or water-based adhesive is rated accordingly (TECHBOND’s water-based wood adhesives are certified D2/D3/D4).

-

If you need high heat or chemical resistance (in a case where the wood component is exposed to heat/fatigue), hot melt adhesives with PO/PUR formulations may be relevant.

5. Equipment & Investment

-

Water‐based adhesives often require pressing and drying capabilities (hot press or other).

-

Hot melt adhesives require melters, applicators, controlled temperature systems. Evaluating cost vs benefit is key.

Why Partner with TECHBOND for Wood Glue Solutions

Here’s why choosing TECHBOND as your adhesive partner can bring value to your wood‐based manufacturing operations:

-

Proven expertise & history: TECHBOND has more than 30 years of experience in industrial adhesives and has factories in Vietnam and Malaysia.

-

Comprehensive manufacturing capability: TECHBOND produces water-based and hot melt adhesives in multiple facilities, with R&D centres and quality control.

-

Tailored adhesive solutions: From water-based to hot melt, and across wood, packaging, automotive and other industries, they offer formulations matched to customer needs.

-

Quality & certification: For instance, their wood adhesives are certified to DIN EN D2/D3/D4 – meaning you can rely on performance for structural/wood‐industry applications.

-

Global reach with local support: With production in Southeast Asia and export to many countries, partner support is available.

-

Sustainability orientation: Highlighted by low VOC, solvent-free choices and energy-efficient bonding technologies.

Practical Tips for Using Wood Glue Effectively

Here are a few practical recommendations to optimize your adhesive use when working with wood glue (whether water-based or hot melt):

-

Surface preparation: Ensure surfaces are clean, dry, free of dust, oil or resin bloom. For oily woods, select a formulation explicitly compatible (TECHBOND’s water-based wood adhesives specify compatibility with oily woods).

-

Follow manufacturer’s instructions: For example, open time, press time, temperature settings, etc.

-

Pressing conditions: For water-based adhesives, use appropriate pressure and allow drying/curing time under specified conditions.

-

Equipment setup: For hot melt adhesives, ensure applicator temperature, melt rate, line speed and compatibility with substrates are all properly configured.

-

Testing & validation: Conduct bond strength tests, especially for critical woodworking joints, edge banding or lamination. If moisture or outdoor exposure is expected, check certifications.

-

Storage & handling: Keep adhesives under recommended storage conditions. For hot melts, ensure pellets or blocks are dry and fed correctly.

-

Waste/rework management: In production, monitor for any peeling, bond failure or inconsistent adhesion and adjust process/adhesive choice accordingly.

Summary

Choosing the right “wood glue” is about more than simply picking an adhesive off the shelf. It means understanding the substrate, the process, the bond requirements and partnering with an adhesive manufacturer who understands your needs.

With TECHBOND, you get access to both water-based adhesive technology (ideal for many wood-to-wood bonding applications, compliant with D2/D3/D4) and hot melt adhesive technology (ideal for high-speed production, non-porous or mixed substrates).

Whether you are in furniture manufacturing, engineered wood panel production, finger-jointing, edge banding or general woodworking, making the right adhesive selection and working with a trusted partner like TECHBOND will help you achieve consistent, high-quality results.