In beverage packaging, straw attachment is a critical process impacting product quality, customer experience, and operational efficiency. Choosing the right adhesive for straw attachment ensures juice and milk boxes maintain secure straw attachment throughout logistics, storage, and consumer use.

Choosing the right adhesive for straw attachment ensures juice and milk boxes maintain secure straw attachment throughout logistics, storage, and consumer use.

This comprehensive guide will help you understand:

- What adhesive for straw attachment is

- Why hot melt adhesive is the best choice

- Key properties to consider

- Application best practices

- Sustainability and compliance in straw attachment adhesives

What Is Adhesive for Straw Attachment?

Adhesive for straw attachment refers to specialized glue used to affix straws to beverage cartons, tetra packs, and pouches during high-speed packaging.

These adhesives:

✅ Deliver fast setting time to match high-speed lines

✅ Ensure strong adhesion to various substrates (OPP film, PET film, PE, laminated paper)

✅ Provide clean application without overflow

✅ Are safe for indirect food contact under FDA and EU regulations

Adhesive for straw attachment refers to specialized glue used to affix straws to beverage cartons

Why Hot Melt Adhesive Is Ideal for Straw Attachment

Hot melt adhesives are the preferred choice for straw attachment in modern beverage packaging lines because they:

- Set Quickly: Solidify within seconds, enabling high-speed production without delays.

- Provide Strong Bonds: Ensure straws remain attached during shipping, storage, and refrigerated conditions.

- Offer Clean Application: Reduce stringing and dripping, maintaining package appearance.

- Reduce Costs: Require low application weights, reducing adhesive usage per unit.

- Work Across Various Substrates: Adhere effectively to OPP, PET, PE films, and laminated paper.

- Support Sustainable Operations: Select hot melts can align with recycling requirements while delivering reliable adhesion.

Hot melt adhesives are the preferred choice for straw attachment

Types of Hot Melt Adhesives for Straw Attachment

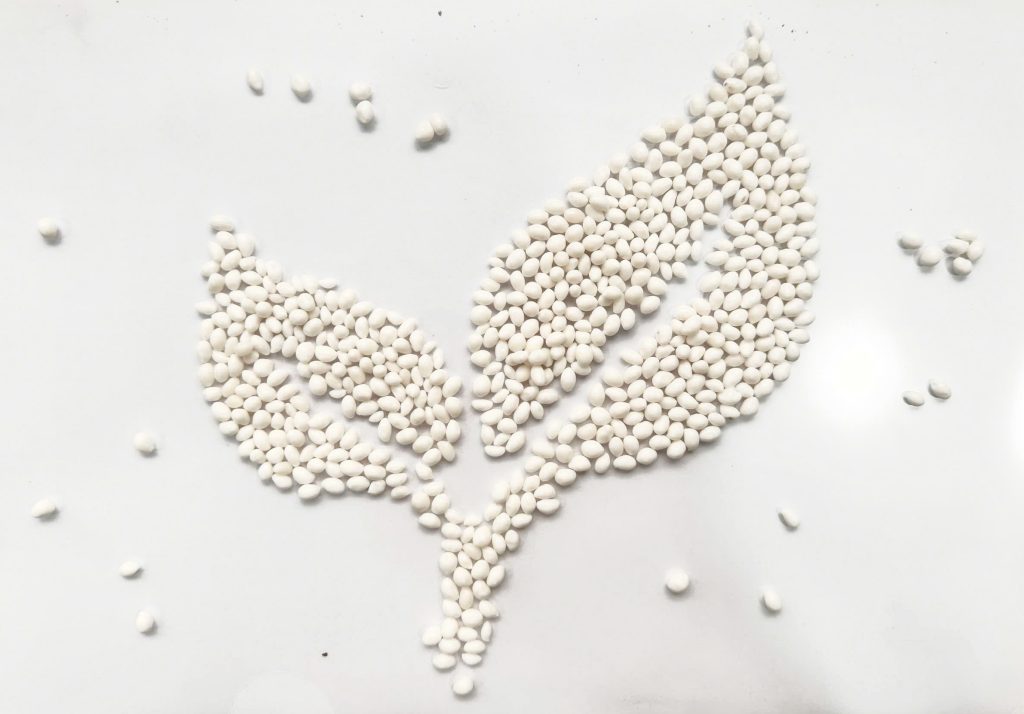

Hot melt adhesives used for straw attachment are typically:

- EVA (Ethylene Vinyl Acetate)-based hot melts: Known for flexibility and general-purpose bonding.

- PO (Polyolefin-based hot melts): Preferred for low odor, clean running, and thermal stability.

Each type offers specific advantages depending on your production requirements, packaging substrates, and line speeds.

Applications of Hot Melt Adhesive in Straw Attachment

Hot melt adhesives are used in:

✅ Straw attachment on juice boxes

✅ Straw attachment on milk boxes

Whether you produce cartons for children’s drinks or flexible pouches for on-the-go beverages, hot melt adhesives provide reliable bonding for your straw application process.

Key Properties to Consider When Selecting Hot Melt Adhesive for Straw Attachment

Choosing the right adhesive ensures efficient operation and strong bonding. Consider:

1️⃣ Adhesion Performance

Hot melt adhesives should bond effectively to your specific substrate:

-

Laminated paper (PET/PE/Aluminum/Board)

-

OPP, PET, PE films

-

Coated or uncoated paper surfaces

Test the adhesive on your actual packaging to confirm compatibility.

2️⃣ Open Time and Setting Time

-

Open time: The period adhesive remains tacky for straw placement.

-

Setting time: How quickly the adhesive solidifies to secure the straw.

For high-speed lines, select adhesives with short open and setting times to prevent straw misalignment.

3️⃣ Viscosity

The adhesive should have:

-

Low enough viscosity for precise dot or line application

-

High enough viscosity to prevent dripping or stringing

4️⃣ Thermal Stability

Choose adhesives that resist thermal degradation in the melter, reducing char formation and nozzle blockages, ensuring consistent adhesive flow.

5️⃣ Temperature Resistance

Your adhesive must maintain bond strength:

-

At high temperatures during shipping

-

At low temperatures during refrigerated storage

6️⃣ Food Safety Compliance

Ensure the adhesive complies with FDA 21 CFR 175.105 and EU 10/2011 for indirect food contact to guarantee consumer safety.

Application Best Practices for Hot Melt Adhesive in Straw Attachment

✅ Apply at Correct Temperature

Use the recommended application temperature (typically 130–160°C) for optimal bonding and viscosity.

✅ Use Suitable Nozzle Sizes

Maintain consistent glue patterns to avoid overflow while ensuring complete adhesion.

✅ Monitor Compression Time

Press the straw onto the adhesive during its open time for secure bonding.

✅ Conduct Regular Maintenance

Clean filters and nozzles to prevent char and ensure consistent adhesive flow.

✅ Store Adhesives Properly

Keep hot melts in a cool, dry area away from sunlight to maintain quality.

✅ Test on Your Actual Line

Always validate performance on your production line before switching adhesives to confirm speed, bond strength, and clean running.

Sustainability in Hot Melt Adhesives for Straw Attachment

As the industry transitions to eco-friendly packaging, consider hot melt adhesives that:

✅ Support recycling processes without contaminating fibers

✅ Have low VOC emissions and low odor for a cleaner environment

✅ Enable easy separation of straws during recycling

Choosing adhesives compatible with recycling and environmentally responsible practices helps your brand align with ESG targets while maintaining performance.

Why Choose TECHBOND Hot Melt Adhesives for Straw Attachment?

TECHBOND specializes in high-performance hot melt adhesives for straw attachment, providing:

✅ Excellent bonding to OPP, PET, PE, laminated cartons

✅ Fast setting for high-speed straw application lines

✅ Low odor and clean machining

✅ Consistent quality with stable supply

✅ Compliance with FDA and EU food safety standards

✅ Technical support to optimize your adhesive usage and reduce costs

Whether you are transitioning to paper straws, improving your straw attachment efficiency, or seeking lower adhesive consumption, TECHBOND can tailor hot melt adhesive solutions to your needs.

Contact TECHBOND for Your Straw Attachment Adhesive Needs

If you are seeking a reliable adhesive for straw attachment for your juice boxes, milk cartons, or beverage pouches, contact TECHBOND today for:

✅ Free adhesive consultation tailored to your production needs

✅ Sample testing to validate adhesive performance on your actual line

✅ Technical support to reduce consumption while maintaining bonding performance

✅ Reliable supply and competitive pricing