In the competitive world of mattress manufacturing, every component contributes to the overall quality, comfort, and longevity of the final product. One of the most essential—but often overlooked—elements is the adhesive used in assembling pocket spring units. For manufacturers aiming to boost efficiency without compromising quality, hot melt adhesives for mattress spring pocket assembly have emerged as the top choice.

What Are Pocket Spring Mattresses?

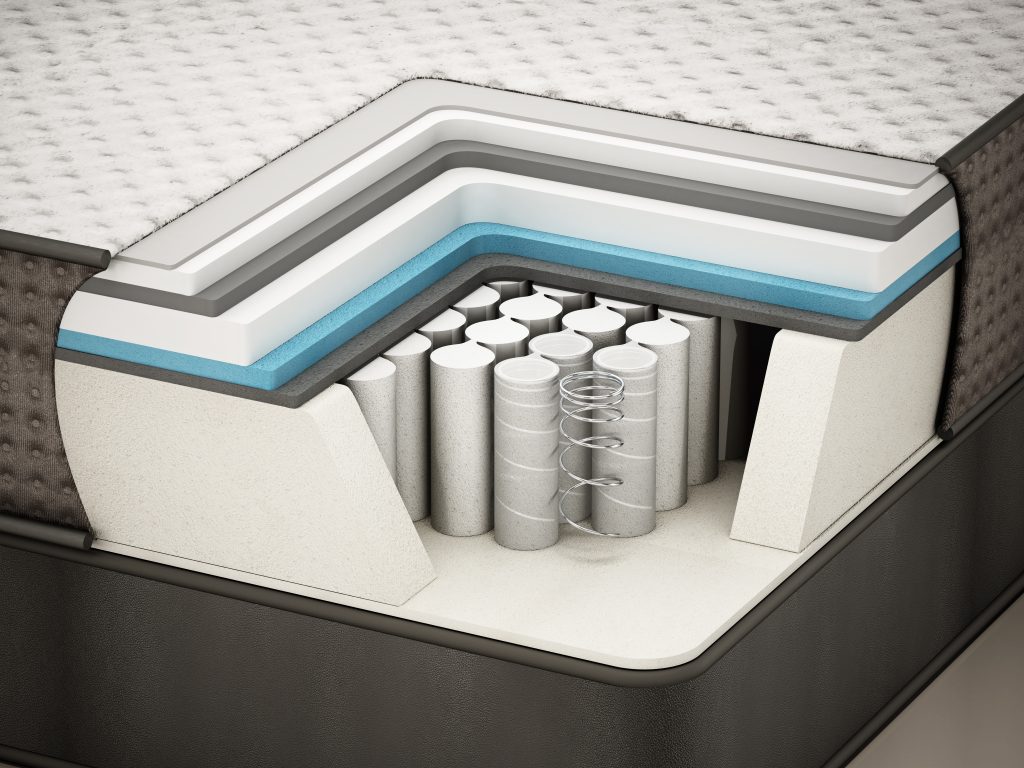

Pocket spring mattresses are made by encasing individual metal coils in fabric pockets. This design allows each spring to move independently, offering superior support and pressure relief compared to traditional innerspring mattresses. These pockets must be sealed securely to ensure the structure remains intact under pressure and over time—which is where high-performance adhesives play a critical role.

Pocket spring mattresses are made by encasing individual metal coils in fabric pockets

Why Hot Melt Adhesives?

Hot melt adhesives (HMA) are thermoplastic resins that are solid at room temperature but become tacky and bondable when heated. Once applied and cooled, they form strong, flexible bonds ideal for many industrial applications—including mattress manufacturing. For pocket spring assemblies, hot melt adhesives are especially advantageous due to the following characteristics:

Fast Setting Time

Hot melt adhesives offer rapid setting after application, enabling faster production cycles. This is particularly important in high-speed mattress assembly lines where every second counts.

Excellent Bonding to Non-Woven Materials

Most pocket springs are encased in non-woven fabric materials. Hot melt adhesives, such as those developed by TECHBOND, demonstrate excellent adhesion to these surfaces, ensuring a durable and consistent bond.

Hot Melt Adhesives for Mattress Spring Pocket Assembly

Low Odour

Manufacturing environments benefit from low-emission products. TECHBOND’s hot melt adhesives are formulated to emit minimal odour, improving workplace air quality and worker comfort during application.

Clean and Efficient Application

Compared to solvent-based or water-based adhesives, hot melt systems produce less waste and eliminate the need for drying time. Their clean application also minimizes stringing and dripping, leading to a more controlled process.

TECHBOND’s Expertise in Mattress Adhesives

At TECHBOND, we understand that not all adhesives are created equal. That’s why our hot melt solutions are specifically engineered for mattress manufacturing, with particular focus on pocket spring assembly.

TECHBOND’s Expertise in Mattress Adhesives

Our range includes adhesives that feature:

-

Short to medium open time (from a few seconds to several minutes), allowing flexibility in various assembly setups.

-

High initial tack that ensures immediate bonding strength.

-

Good heat resistance to maintain bond integrity during further processing like rolling or packaging.

-

Flexibility to accommodate the dynamic movements and pressure distribution within the mattress.

These properties make TECHBOND hot melt adhesives not only reliable but also cost-effective for large-scale production.

Applications in Mattress Assembly

Pocket Spring Assembly

The primary use of hot melt adhesives in this area is bonding non-woven fabric to seal individual spring pockets. The adhesive must be strong enough to hold the pockets securely while remaining flexible enough to allow the springs to operate independently.

Hot melt adhesives can be applied for different application in mattress manufacturing

Layer Bonding

Apart from pocket spring units, TECHBOND hot melt adhesives are also effective in bonding foam, felt, and other padding layers to the core structure of the mattress. This ensures uniform layering and prevents material shifting.

Edge Support Bonding

Hot melt adhesives are used to fix edge supports and perimeter foam, enhancing the structure and lifespan of the mattress.

Environmental and Operational Benefits

In addition to superior bonding performance, TECHBOND’s hot melt adhesives contribute to greener and safer production practices:

-

No solvents = no VOCs: Our adhesives are solvent-free, reducing environmental impact and ensuring compliance with global health and safety regulations.

-

Energy efficiency: Fast processing reduces the need for extended curing equipment, saving energy and reducing operational costs.

-

Worker safety: With low odour and clean handling, the working environment is safer and more pleasant.

Choosing the Right Hot Melt Adhesive

Selecting the right adhesive depends on several factors, including substrate type, production speed, and application method (e.g., spray or bead). TECHBOND offers a variety of formulations to suit different mattress manufacturing needs, all developed through rigorous R&D and customer feedback.

We recommend working closely with our technical team to identify the optimal product for your specific process. Custom solutions and technical support are always available to ensure maximum performance.

Conclusion

Hot melt adhesives for mattress spring pocket assembly offer unmatched efficiency, bonding performance, and operational benefits. As mattress manufacturers look to innovate and scale, choosing the right adhesive partner is crucial. TECHBOND stands ready with reliable, high-performance hot melt solutions tailored to the evolving needs of the industry.

Whether you’re launching a new mattress line or looking to optimize your current process, TECHBOND’s hot melt adhesives deliver the reliability, speed, and quality your production line demands.

Not sure which adhesive is right for your application?

Get in touch with us today for expert advice